Consumers will be most familiar with Expanded Polystyrene (EPS) as a packaging material for goods such as televisions and food, and the insulation inside portable coolers. It’s also used in both commercial and residential applications for insulating external walls, roofs, and foundations in homes.

Lightweight, highly energy-efficient and cheaper than traditional materials, EPS has been a sought-after choice for homeowners and builders since it came onto the Australian market in the 1980s. It gained popularity in the building industry as external cladding, as it doesn’t rot or attract vermin like rats or termites.

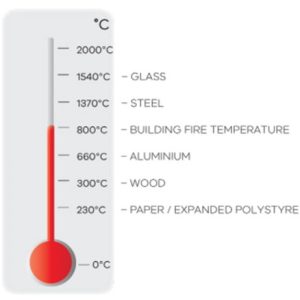

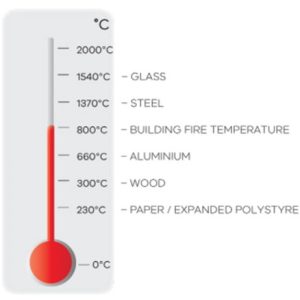

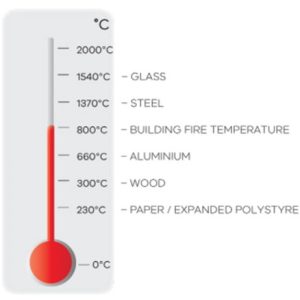

However, there have been growing concerns around the fire behaviour and risks associated with the use of rendered EPS (with fire retardant) in Australian homes and properties. As EPS is derived from petroleum, it ignites at far lower temperatures than other building materials. A kilogram of polystyrene will release more energy than a litre of petrol, so when it burns, it burns hot and fast, while also emitting highly toxic ‘black smoke’ in the process.

While the use of EPS was banned on multistorey apartment buildings by the Victorian government in 2021, its use remains unrestricted on detached homes and multistorey townhouse projects.

The standard response time for fire services to reach a structure fire is 7.7 minutes, but blazes featuring EPS can fully engulf a home in just five minutes – Fire Rescue Victoria.

The Dangers Of EPS

From fire safety challenges to environmental impact and health concerns, understanding the dangers of EPS insulation is essential for informed home construction choices.

Fire Hazard:

One of the most pressing dangers associated with EPS in Australian homes is its combustibility. EPS is highly flammable, and in the event of a fire, it can ignite quickly and contribute to the rapid spread of flames. This poses a significant threat to the safety of both property and inhabitants. While EPS is typically treated with flame retardants, these chemicals can lose their effectiveness over time, especially in the presence of moisture or UV exposure.

In regions prone to bushfires, the risk is even more pronounced. The intense heat and flying embers generated by bushfires can easily set EPS ablaze, leading to the rapid advancement of fires and placing lives and property in jeopardy.

Toxic Emissions

When EPS burns, it releases toxic smoke and fumes, including carbon monoxide and hydrogen cyanide. Inhaling these harmful substances during a fire can lead to severe health consequences for those inside the building, including occupants and firefighters.

Environmental Impact:

EPS is made from petroleum-based materials, and its production consumes non-renewable resources and generates greenhouse gas emissions. Additionally, EPS is not biodegradable and can persist in the environment for centuries. When disposed of improperly, EPS can contribute to pollution and harm wildlife.

Thermal Performance in Extreme Climates:

While EPS insulation performs well in moderate climates, its effectiveness diminishes in extreme Australian conditions. In regions with scorching summers or chilly winters, EPS may struggle to maintain desired indoor temperatures, leading to increased energy consumption and discomfort.

Moisture Vulnerability:

In regions prone to heavy rainfall and humidity, EPS insulation can be susceptible to moisture infiltration and condensation if it’s not installed properly. Moisture can reduce its thermal performance and potentially lead to mould growth, posing health risks to occupants.

Credit: Victorian Building Authority

Alternatives To Using EPS In New Homes And Renovations

Alternatives to using EPS in new homes and renovations

Below are three alternatives to EPS that offer a balance of fire safety, cost-effectiveness and thermal performance:

1. AAC (Autoclaved Aerated Concrete) Cladding: AAC cladding offers outstanding fire resistance and thermal insulation. These panels are known for their lightweight, durable and versatile properties. They are eco-friendly, non-combustible, and are compliant as external wall cladding in all Australian bushfire regions.

2. Fibre Cement Cladding: Fiber cement cladding, such as HardiePlank, is a popular choice due to its exceptional fire resistance and durability. It requires minimal upkeep, is resistant to termite and pest damage, and also offers good thermal insulation properties when installed with appropriate insulation materials.

3. Brick Cladding: Traditional brick cladding has excellent fire resistance and provides thermal mass, helping to regulate indoor temperatures. It is commonly used in new homes and can be an attractive option for renovations, offering a classic and timeless aesthetic.

While EPS cladding comes with insulation benefits and cost advantages, it's crucial for homeowners, builders, and architects to be aware of the hidden dangers it presents. Exploring alternative cladding materials when building or renovating a home that offer better fire resistance and safety is essential to mitigate these risks effectively and ensure the safety and well-being of both properties and their occupants.

Consumers will be most familiar with Expanded Polystyrene (EPS) as a packaging material for goods such as televisions and food, and the insulation inside portable coolers. It’s also used in both commercial and residential applications for insulating external walls, roofs, and foundations in homes.

Lightweight, highly energy-efficient and cheaper than traditional materials, EPS has been a sought-after choice for homeowners and builders since it came onto the Australian market in the 1980s. It gained popularity in the building industry as external cladding, as it doesn’t rot or attract vermin like rats or termites.

However, there have been growing concerns around the fire behaviour and risks associated with the use of rendered EPS (with fire retardant) in Australian homes and properties. As EPS is derived from petroleum, it ignites at far lower temperatures than other building materials. A kilogram of polystyrene will release more energy than a litre of petrol, so when it burns, it burns hot and fast, while also emitting highly toxic ‘black smoke’ in the process.

While the use of EPS was banned on multistorey apartment buildings by the Victorian government in 2021, its use remains unrestricted on detached homes and multistorey townhouse projects.

The standard response time for fire services to reach a structure fire is 7.7 minutes, but blazes featuring EPS can fully engulf a home in just five minutes – Fire Rescue Victoria.

The Dangers Of EPS

From fire safety challenges to environmental impact and health concerns, understanding the dangers of EPS insulation is essential for informed home construction choices.

Fire Hazard:

One of the most pressing dangers associated with EPS in Australian homes is its combustibility. EPS is highly flammable, and in the event of a fire, it can ignite quickly and contribute to the rapid spread of flames. This poses a significant threat to the safety of both property and inhabitants. While EPS is typically treated with flame retardants, these chemicals can lose their effectiveness over time, especially in the presence of moisture or UV exposure.

In regions prone to bushfires, the risk is even more pronounced. The intense heat and flying embers generated by bushfires can easily set EPS ablaze, leading to the rapid advancement of fires and placing lives and property in jeopardy.

Toxic Emissions

When EPS burns, it releases toxic smoke and fumes, including carbon monoxide and hydrogen cyanide. Inhaling these harmful substances during a fire can lead to severe health consequences for those inside the building, including occupants and firefighters.

Environmental Impact:

EPS is made from petroleum-based materials, and its production consumes non-renewable resources and generates greenhouse gas emissions. Additionally, EPS is not biodegradable and can persist in the environment for centuries. When disposed of improperly, EPS can contribute to pollution and harm wildlife.

Thermal Performance in Extreme Climates:

While EPS insulation performs well in moderate climates, its effectiveness diminishes in extreme Australian conditions. In regions with scorching summers or chilly winters, EPS may struggle to maintain desired indoor temperatures, leading to increased energy consumption and discomfort.

Moisture Vulnerability:

In regions prone to heavy rainfall and humidity, EPS insulation can be susceptible to moisture infiltration and condensation if it’s not installed properly. Moisture can reduce its thermal performance and potentially lead to mould growth, posing health risks to occupants.

Credit: Victorian Building Authority

Alternatives To Using EPS In New Homes And Renovations

Alternatives to using EPS in new homes and renovations

Below are three alternatives to EPS that offer a balance of fire safety, cost-effectiveness and thermal performance:

1. AAC (Autoclaved Aerated Concrete) Cladding: AAC cladding offers outstanding fire resistance and thermal insulation. These panels are known for their lightweight, durable and versatile properties. They are eco-friendly, non-combustible, and are compliant as external wall cladding in all Australian bushfire regions.

2. Fibre Cement Cladding: Fiber cement cladding, such as HardiePlank, is a popular choice due to its exceptional fire resistance and durability. It requires minimal upkeep, is resistant to termite and pest damage, and also offers good thermal insulation properties when installed with appropriate insulation materials.

3. Brick Cladding: Traditional brick cladding has excellent fire resistance and provides thermal mass, helping to regulate indoor temperatures. It is commonly used in new homes and can be an attractive option for renovations, offering a classic and timeless aesthetic.

While EPS cladding comes with insulation benefits and cost advantages, it's crucial for homeowners, builders, and architects to be aware of the hidden dangers it presents. Exploring alternative cladding materials when building or renovating a home that offer better fire resistance and safety is essential to mitigate these risks effectively and ensure the safety and well-being of both properties and their occupants.